|

FÖRDER_DYNAMIC Schüttgutanlagentechnik GmbH is a B&K subsidiary specialising in pneumatic dense phase conveyance technologies.

Dense phase conveyance is a pneumatic form of conveying large quantities of raw materials from A to B designed to have minimal effect on the materials themselves.

Protects the product / Low wear-and-tear

|

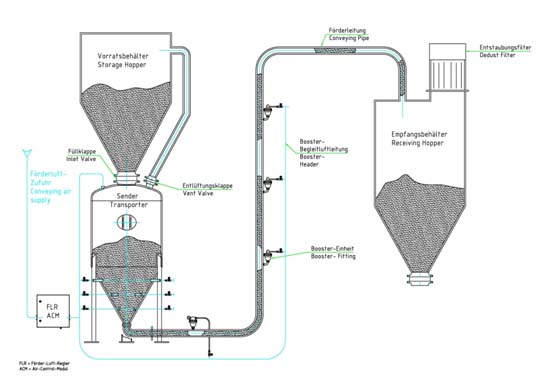

In thsi example the operating principle is shown using a sender conveyor

In thsi example the operating principle is shown using a sender conveyor

|

|

Sender Conveyor:

The filling begins when the filling and vent valves are opened.

The sender fills up quickly, because the displaced air can escape unhindered via the separate vent. Upon reaching the fill level (level switch), both valves close again, with the locking position checked by the limit switch. Compressed air is pumped into the sender and the material is compressed with the highest possible density to the conveyor, thus creating a very efficient conveyance process. After conveyance is finished,

the air pressure drops and the air supply automatically shuts off. The sender is now ready for the next conveyance cycle.

To achieve higher capacities, conveyance can also take place via a high pressure rotary feeder. |

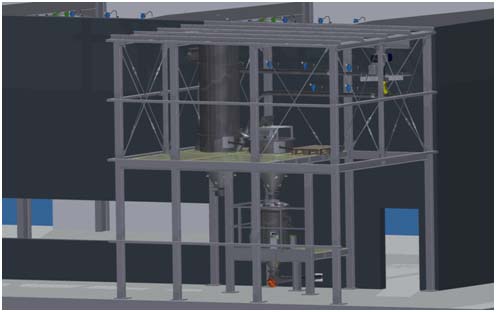

Test Lab

B&K has its own test laboratory with a 110m conveyor distance so that it can test your product's integrity and conveyance performance. This can be tested with both the sender conveyor and the rotary feeder.

Please contact our team to set up a product trial in our facility.

Our test lab offers a conveyance distance of 110m

Our test lab offers a conveyance distance of 110m

to allow product tests to be performed

|

|

Sender Design:

Each standard sender can be designed accordingly or customized to solve even the most difficult conveyance requirements. The sender containers are also available in different materials and sizes on request.

Technical specifications:

Operating pressures:

0 to max 7 bar

Sender container-volumes:

100 - 5000 dm3

Tonnages:

depending on the bulk density, up to 150 tonnes / hour

Bulk densities:

0,1 to 5kg/dm3

Product temperatures:

from -20 to +150 °C (potentially up to 300°C)

Conveyor lines lenth:

up to about 600m

Feed pipe diameter:

DN50-DN300

|

Materials in sender container:

- normal steels

(for the building materials industry)

- stainless steels

(for the chemical industry)

- low-chrome and nickel-free

(content max. 0.5% for the glass industry)

- construction in special steels possible

|